IMPEL: Propelling Emerging Building Technologies to the Forefront of Construction

Packaging innovative ideas to appeal to investors can be challenging. Here’s how the DOE-funded program can help.

IMPEL—short for Incubating Market-Propelled Entrepreneurial Mindset at the Labs and Beyond—is a program funded by the U.S. Department of Energy’s Building Technologies Office and implemented by the Lawrence Berkeley National Laboratory.

Launched in 2020 with Reshma Singh as director, IMPEL is a reaction to Singh’s “personal passion to create entrepreneurship programs that connect the labs with innovators in the public and private sectors,” as she describes it. Because despite her expansive knowledge and unending curiosity for all things at the intersection of design and technology of smart buildings and cities, she had challenges bringing her clean-tech patents to market.

It’s noteworthy to share that the Lawrence Berkeley National Lab is one of the DOE’s 17 national labs across the country. Scientists working in these national labs are winners of 118 Nobel Prizes combined and discovered 22 elements on the periodic table. These hubs are vital for science and technology collaboration. It is here where critical technologies are being developed, innovations that could be used in the climate change fight, as opposed to existing greenwashing “solutions.”

Helping the commercialization of early-stage building technologies

All early-stage innovators bump into the same problem: overcoming what the start-up world calls “the commercialization valley of death,” the phase between developing a prototype and going to market with a commercially viable building product. IMPEL facilitates access for these innovators to the other side of business by connecting them with mentors and teachers who coach them in creating business plans, pitching and soft skills.

These facilitators also offer technical feedback on construction and building materials, and train innovators on using carbon tools that help quantify the climate benefits of their creations. Then, they provide exposure to funding opportunities, in both the public and private sectors, and introduce them to IMPEL’s partner business incubators and the world-class National Lab ecosystem.

As of June 2023, IMPEL had 213 innovator teams, ranging from prefabricated construction to sustainable eco-studs, to highly efficient energy and water equipment. The program has 24 mentors—subject-matter experts from the national laboratories, policy and demonstration experts, and investors extending from climate tech venture investment firms to corporate venture capital and large banks. The IMPEL network also includes three coaches from the Silicon Valley ecosystem and has three national showcases: HUD’s Innovative Housing Showcase at the National Mall, IMPEL national showcase by the Department of Energy’s Building Technologies Office and IMPEL Building Sector Pitch Day at Greentown Labs climate tech incubator.

READ ALSO: Hines’ Trifecta for Carbon Emissions Reduction

Candidates for the IMPEL program must have ideas with potential for significant carbon reduction in the building sector.

“This aligns with the IMPEL vision of a net-zero built environment validated through carbon tools, promoting equitable wellness and resilience for all,” explained Singh. “Their ideas must have a strong value proposition for the building construction industry, as validated by mentors who assess the potential market and sales fit,” she added. But there’s also an intangible attitude that mentors can sense—candidates’ drive or passion to bring innovative products to the market.

Here are some of the remarkable ideas that have turned real with IMPEL, so far:

- InventWood—winner of a $20 million ARPA-E SCALEUP award. The entity develops and manufactures lightweight 3D wood corrugated honeycomb structures to replace metal counterparts in the construction of buildings and reduce carbon dioxide manufacturing emissions by 90 percent.

- Flower Turbines has raised more than $11 million in equity crowdfunding and makes quiet, compact and efficient wind turbines. The company has begun sales and manufacturing in Texas.

- Sensfix received a $2.5 million grant from the EU and $475,000 in angel funding. Its platform uses multimodal AI and mixed reality to digitalize workflows in the operations and maintenance of buildings and industrial facilities.

- Shower Stream is running a $750,000, 18-month demonstration project with the Department of Defense. Its technology uses AI to manage excessive energy and hot water waste in real-time across multiple buildings. It has also piloted a project with Extended Stay America, which has more than 65,000 hotel rooms.

Standout ideas in IMPEL’s current pipeline

Okom wrks labs is developing the world’s strongest mycelium-based biocomposite (MBC)—dubbed zerø-frm—capable of serving in structural applications in the built environment to create and commercialize a prefabricated SIP wall. The claim of being “the world’s strongest MBC” is the result of their analysis of the available data on the structural mechanics of known MBC formulations.

Behind it is Joshua English, an artist and designer with a “not so mild” obsession with materials, as he puts it. Instead of just accepting the given options on the market and trying his best, he let his mind wander.

“The deeper I explored the mycelium lifestyle, the more I realized that the key to unlocking the full potential of the fungal mycelium for the built environment was to mimic the familiar settings and nutrition that the fungus would find in nature,” English said.

This meant months of field observation, “on your belly in the forest, looking at centimeters of forest floor with a magnifying glass.” Then, those insights were brought back into the lab, where the same conditions were created to coax uniformity in the growth of the mycelium from one part to the next—temperature, humidity, oxygen and carbon dioxide levels, pH and the substrate of the substratum.

“The combinations are nearly limitless, and small adjustments can make the world of difference. So, finding a process that can standardize what is seemingly inescapably stoichiometric is the main goal of this type of material research. So, no pressure there,” he joked.

The IMPEL program was ideal for okom wrks, according to English. IMPEL showed them how to pack their technology for a wider audience.

“We were a part of the 2021-22 cohort. Each session that we participated in made our business case clearer and, therefore, easier to communicate. We also were able to benefit from access to industry experts who know the tough road that bringing building materials to the market entails,” English said.

Applicability in real estate developments

When asked how his structural mycelium can improve the construction process, English responded via simple arithmetic.

“We can produce four to six times more building material on an acre of farmland, without displacing food production, than can be extracted from an acre of forest. So, what makes the material truly disruptive is that it provides a similar level of service as the incumbent technologies, with fewer costs—both to the bottom line and to the planet. So first and foremost, it’s cheaper, which is unusual for an emergent technology,” he detailed.

okom wrks is gearing its process and the materials it creates to work well in the modular building arena. The most important aspect, however, is that zerø-frm will be a carbon-storing material with a negative amount of embodied carbon. This means that it will store more carbon than it was emitted in the creation of the material. okom wrks expects to get the first products to the market within 18 to 24 months.

PLAY PODCAST: Sustainability Street—How Trammell Crow Is Cutting Carbon

Eliot Kahn, CEO, HumanKind Homes. Image courtesy of HumanKind Homes

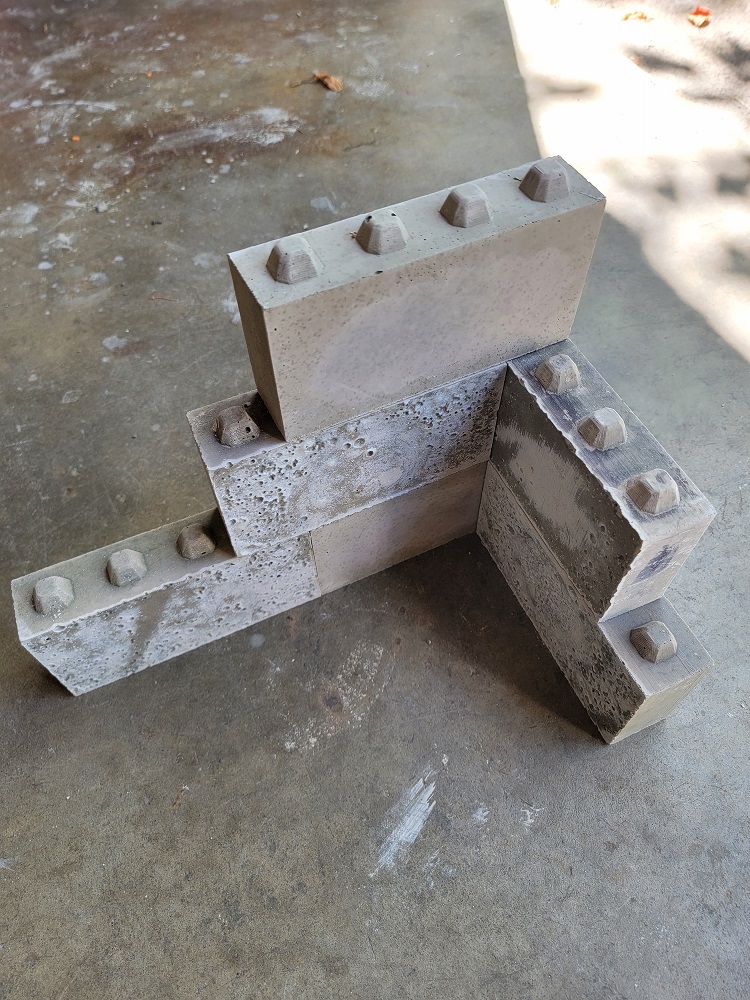

HumanKind Homes is another IMPEL innovator. The full-service design-build construction company develops affordable, sustainable and healthy buildings using its proprietary technology. HumanKind Homes designs, pre-manufactures and builds every part of the structure using bricks, beams, panels and foam made from sustainable geopolymer concrete sourced from local recycled materials.

The KindBlock system was designed as a sustainable alternative to traditional construction methods, explained CEO Eliot Kahn. His team designed this solution for all types of buildings, from small homes to commercial high-rises. The KindBlocks form a kit of interlocking bricks, beams and panels that resemble Lego parts. Made from a single material—geopolymer concrete—they attain much lower manufacturing requirements while being able to provide a greater amount of customizability.

Ultimately, HumanKind Homes aims to develop a completely sustainable and automated end-to-end system across the design, manufacture and build process, scalable anywhere.

“Assembling a pre-manufactured kit of human-scale construction pieces reduces labor and material costs, and cuts build time down,” Kahn said. “By addressing more parts of both the product and process than other technologies, we are able to design a solution to a wider set of problems across the value chain, which reduces costs and increases flexibility. This allows us to approach different parts of the market and scale in ways that other technologies just aren’t capable of,” he added.

IMPEL helped HumanKind Homes in two major ways: It refined the way the company communicated about its business model to potential investors, while also assisting with enhancing their education on carbon analysis tools. The company is now building a pilot project using products produced at its own manufacturing facility opened this year.

EcoSnap is another notable IMPEL candidate. It features a connection technology for ductless mini split heat pumps and it was launched by Diana Fisler, CEO & building material scientist. These pumps are ideal for heating and cooling single zones or particular rooms in a home—which traditionally comes with high costs for many homeowners.

“EcoSnap eliminates the need for an electrician and an HVAC technician usually required for installation, reducing cost and complexity. This patented connection innovation puts a simple efficient heat pump within reach of a typical homeowner,” Fisler explained. EcoSnap is collaborating with a prototyping company to produce several prototypes and bring them into the field for demonstration this summer.

IMPEL’s measurements of success

Reshma Singh, Program Director, IMPEL. Image courtesy of the U.S. Department of Energy’s Building Technologies Office

Money talks so funding is a key metric to measure the program’s success. “It shows that investors believe in what these innovators are doing,” said Singh. So far, IMPEL alumni have raised more than $90 million. In addition, IMPEL innovators have created about 160 jobs.

Awards, grants, prizes and pilot programs are another telling sign of things done right. These show serious interest on the part of government agencies, incubators and other institutions and, so far, innovators have won 167 of these, shared Singh.

Additionally, IMPEL is committed to diversity—innovators represent 26 U.S. states and territories, with 54 percent being women and/or people of color, added Singh. “We’re drawing innovators across generations as well, from people in their 20s to people who are old enough to retire,” she said.

Looking into a decarbonized future

Political will has a profound effect on anything related to climate change. Not just that a program like IMPEL exists because political will allows it, but smart policies can foster innovation.

“And federal investments in technology make an enormous difference. Remember that government investment led to the Internet, radar, GPS and countless other technologies,” said Singh.

Reaching net-zero built environments is doable, and IMPEL representatives have a three-point plan:

- Reducing embodied and operational emissions;

- Digitalizing toward connection—possible by connecting equipment, buildings and energy systems with organizations and decision-makers;

- Democratizing through community—which means a greater focus on wellness and empowering human capacity, inclusive resilience and community participation in clean energy solutions.

The IMPEL concept has recently expanded beyond the built environment with a new initiative, called Cradle to Commerce. It includes other areas key to decarbonization, such as transportation, renewable energy and smart grids, added Singh.

“We just started up this year and we’ve added a matchmaking component between intellectual property owned by the national labs and entrepreneurs who want to bring decarbonizing technologies to market. This is another project backed by the Department of Energy, and it involves Berkeley Lab and three other national labs,” Singh revealed.

You must be logged in to post a comment.